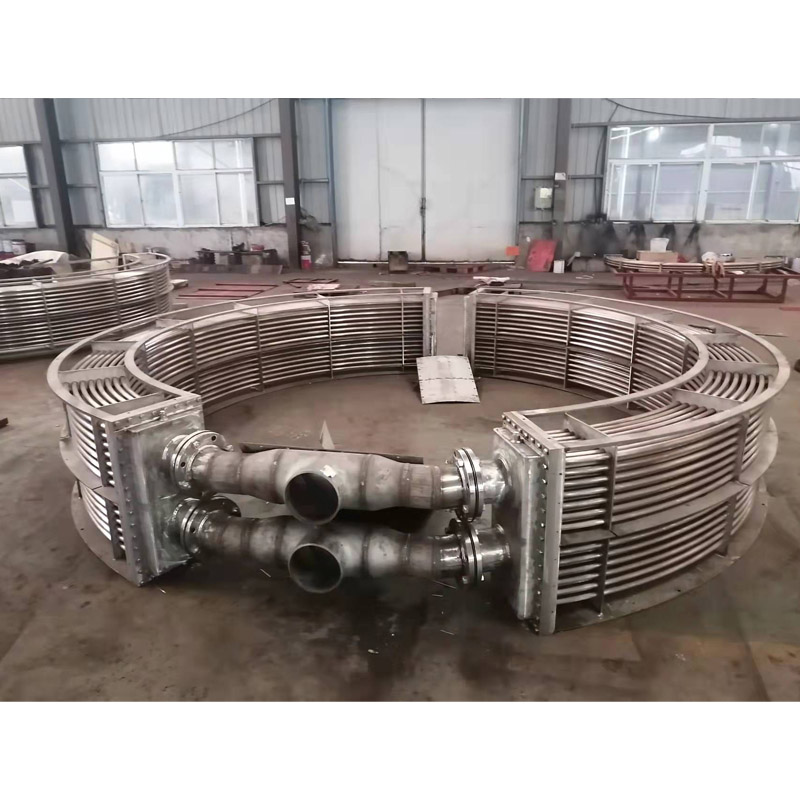

200MW hydroelectric generator unit bearing cooler-coil structure

The purpose of the bearing cooler is to remove the heat generated in the lubricating oil by the operation of the machine. Typically water is used as the cooling fluid for a Bearing Cooler. Common Bearing Cooler applications are in large motors, hydro electric generators (thrust or guide bearings), compressors and any other high speed rotating equipment. Bearing coolers are varied in type and can take on many forms. They are seldom “standard designs” so manufacturing replacement coolers requires knowledge, experience, and flexibility

1.Thrust bearing oil cooling coils manufactured in two half sections for ease of installation.

T2/3003 bimetal finned tube

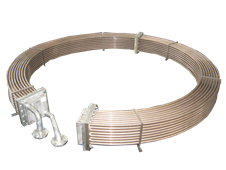

2,Multiple material combination,Turbine guide bearing oil cooling coil with copper - nickel tubes, extruded aluminum fins and brass connection fittings.

3,Professional design and customizatioin. Leader Heat exchanger offers broad range of materials in multiple designs with different sizes to choose from to satisfy any cooling water conditions and to suit Customer’s specific requirements.

There are 4 Common designs as below:

Circular-one piece type

One piece / drop-in design

Finned or Bare Tube

Pipe Headers or Box Header design

Circular-sectional type

Two or more segmental pieces

Installed in sections to take a circular form

Finned or Bare Tube

Pipe Headers or Box Header design

Bare Tube Type

Can be replaced with finned tube coolers that match dimensionally but with increased cooling capabilities.

Finned Tube Type

Identical replacements of existing coolers or uprated performance.

Aluminum or copper finned tube

Variety of fin attachment types.

Can be designed to match existing finned tube or bare tube designs