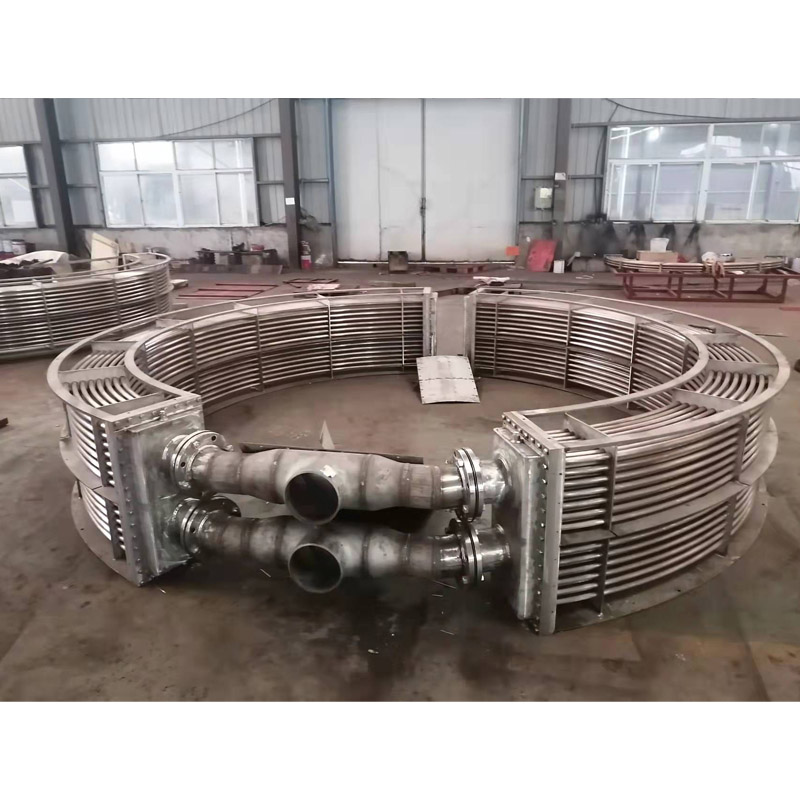

Bearing cooler-coil structure hydroelectric generator set-oil and water

Bearing Oil Cooler, including thrust bearing oil coolers and guide bearing oil coolers, for bearings in hydro electric generators can be custom manufactured for new projects, or to replace your faulty existing units. We can come on site to measure your cooler or you can ship it to us and we can replace it in kind. When required, we can provide an upgrade to facilitate current conditions.

Bearing oil coolers can be manufactured with our Helically Wound Finned Tubes, soldered fin-to-tube attachment, but coolers with bare or prime surface tubes can also be produced. While 90/10 CuNi tubes are most common, units can also be manufactured with a variety of other tube materials including copper, admiralty brass, numerous types of stainless steel and carbon steel . One of the product we showed used T2/3003 bimetal finned tube with aluminium fins.

1,Thrust bearing oil cooling coils manufactured in two half sections for ease of installation.

T2/3003 bimetal finned tube

2,Multiple material combination,Turbine guide bearing oil cooling coil with copper - nickel tubes, extruded aluminum fins and brass connection fittings.

3,Professional design and customizatioin. Leader Heat exchanger offers broad range of materials in different sizes to choose from to satisfy any cooling water conditions and to suit Customer’s specific requirements.