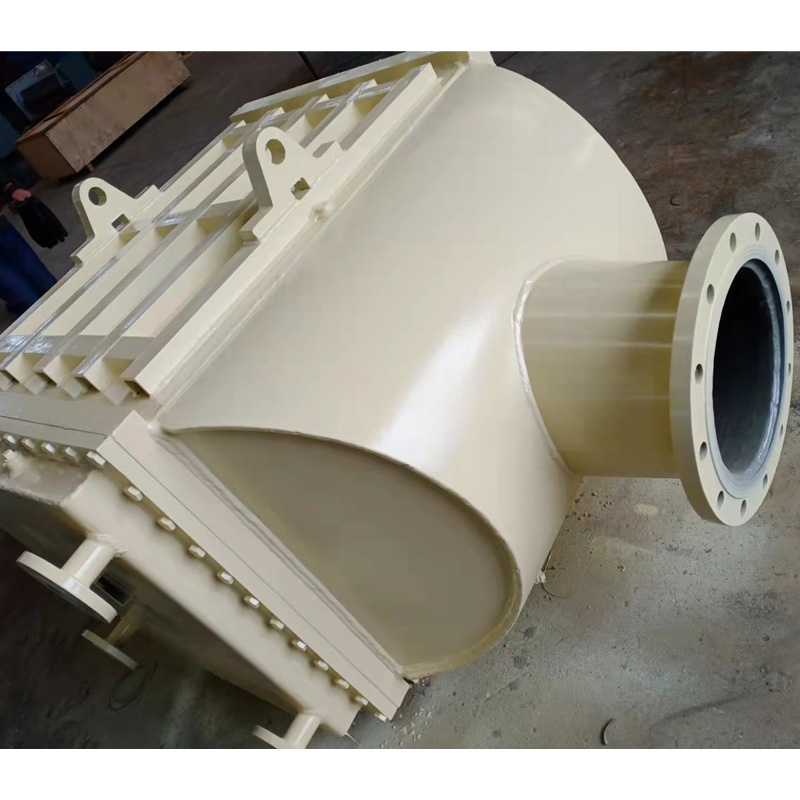

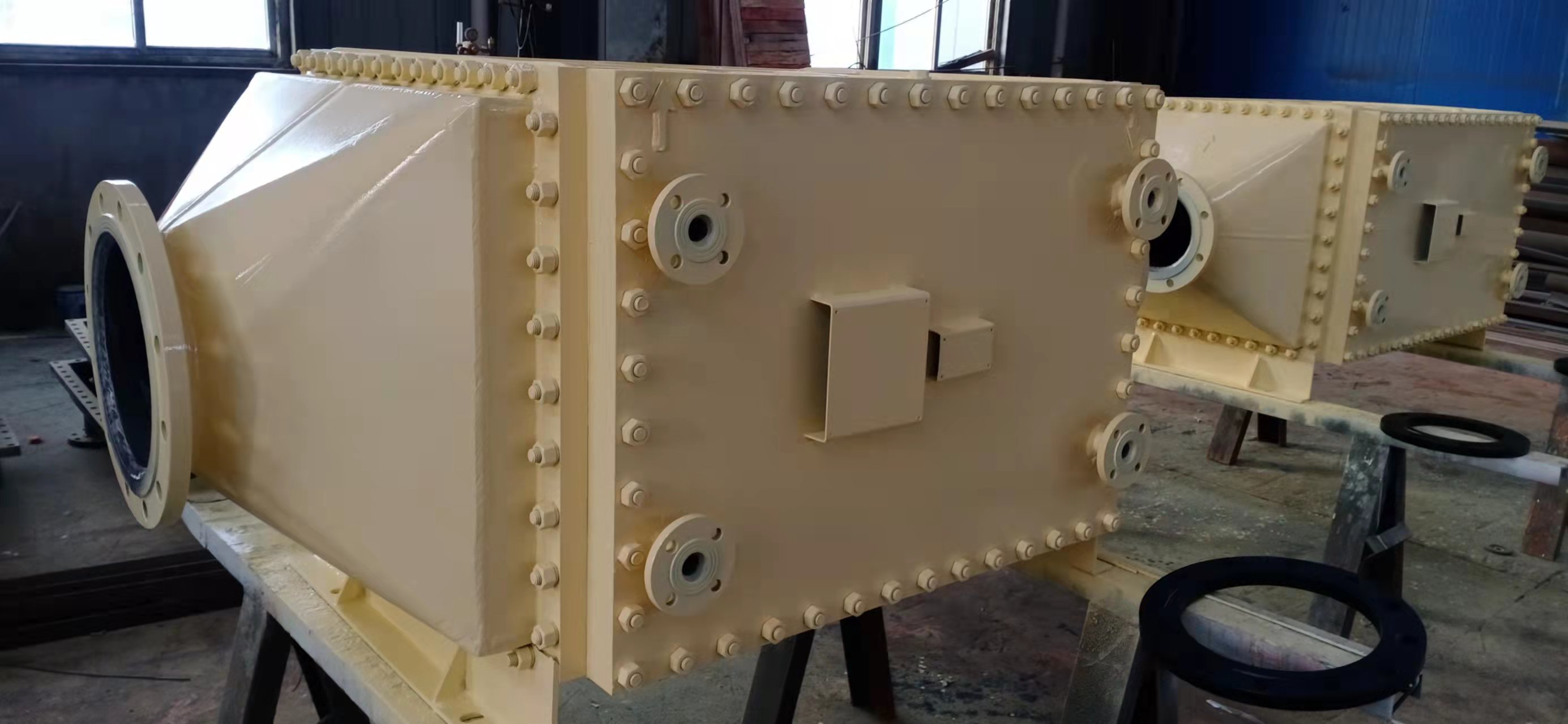

Heater tube fin Type - Compressor Waste Heat Recovery Hot Air and Water

This heater is used in collecting waster heat produced in various industrial equipments.Industrial waste heat is rich in resources and widely exists in the production process of various industries. Waste heat resources account for about 17% to 67% of its total fuel consumption. Among them, the recovery rate is 60%. The utilization rate of waste heat is greatly improved, and the energy saving potential is huge.

The flue gas waste heat is large and the temperature distribution range is wide, accounting for more than 50% of the total industrial waste heat resources, and it is widely distributed, such as metallurgy, chemical industry, building materials, machinery, electric power and other industries, various smelting furnaces, heating furnaces, internal combustion engines and boilers. Exhaust and smoke, and the waste heat of flue gas in some industrial kilns is even as high as 30% to 60% of the fuel consumption of the kiln itself. It has great energy saving potential and is the main object of waste heat utilization.

The waste heat of chemical reaction accounts for less than 10% of the total waste heat resources, mainly in the chemical industry. High-temperature products and slag waste heat mainly refer to the sensible heat of billets, coke, slag, etc., and the sensible heat of oil and gas products in the petrochemical industry. Combustible waste gas and waste heat refer to the exhaust gas, liquid discharge and slag discharge of the production process that contain combustible components, such as blast furnace gas and converter gas in the metallurgical industry.

We use the latest domestic design software for product design calculations.

1 Thermal Design Computational Design (HTRI)

2 3D (AUTO CAD) working software for complex system we 3D stereoscopic design.

3 Powerful ANSYS finite element strength analysis software

4 Perfect pressure vessel design safety analysis software

5 Heat transfer simulation analysis

6 Fluid flow simulation analysis

7 Analysis of structural mechanical properties

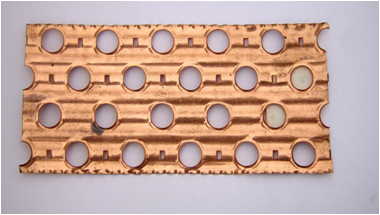

Advanced heat exchanger elements we are using

Aluminium fin plate

Copper fin plate